Community

Press Release

2023-11-17

Computer Mate develops customized AI solution for automobile parts production line

AI convergence support results for Daegu transportation equipment and mechanical material parts… Prepare in advance by predicting defects or unexpected breakdowns in production facilities and testing equipment

Provided to Gyeongchang Industry and Pyeonghwa Industry, contributing to improving work efficiency

We are participating as an artificial intelligence (AI) supplier in the Daegu transportation equipment and mechanical materials and parts field hosted by Daegu Techno Park in the 'AI Convergence Regional Specialized Industry Support Project' promoted by the Ministry of Science and ICT and the National IT Industry Promotion Agency (NIPA). Computer Mate (CEOs Sang-in Seo and Seong-ho Kim) announced that it had provided a production line optimization AI solution to Gyeongchang Industry, an automobile parts company, and an AI-based test equipment failure prediction solution to Pyeonghwa Industry. Among these, the solution supplied to Gyeongchang Industries is scheduled to be applied to overseas production sites, so people in related industries are paying attention.

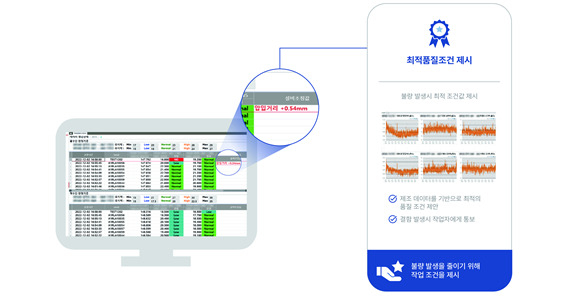

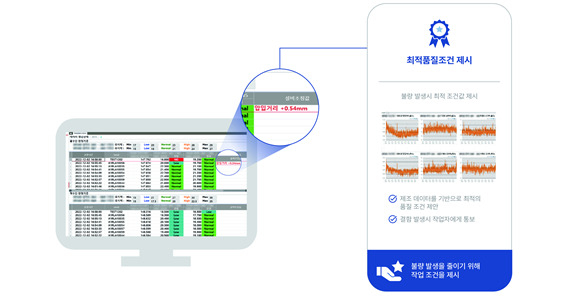

Computer Mate developed a production line optimization AI solution aimed at minimizing product defect rates and applied it to the actuator line of the chassis factory of Gyeongchang Industrial, a customer company. This solution uses AI to automatically recommend facility condition values, analyzes the correlation between data generated at the production site and the defect rate, and through AI learning, derives optimal facility operation conditions that minimize the defect rate. In particular, in preparation for sudden breakdowns or defects in actuator production/manufacturing facilities and inspection facilities, condition information on the operation status of the equipment is collected and monitored in normal times, and AI determines quality abnormalities in advance through learning and analysis to conduct preventive inspections and advance Action can be taken.

Accordingly, not only can worker dependence be reduced, but defects occurring in the manufacturing process can be reduced, and productivity can be increased through rapid response to abnormal situations and reduction of rework. Computer Mate explained that as a result of using this solution, productivity is expected to increase by 7% per year.

Computer Mate and Gyeongchang Industrial are in the spotlight as exemplary models of cooperation between supply and demand companies that participated in the ‘AI Convergence Regional Specialized Industry Support Project’. The two companies judged that this solution had been sufficiently verified in terms of minimizing defect rates, and agreed to introduce this solution into the process management system (MES) of Kyungchang Industrial's local Mexican branch within this year. The contract size is $100,000. In addition, Gyeongchang Industrial plans to apply an AI-based vision system to the transmission drive device of the Hyeonpoong factory next year, and to use AI models to predict the quality of CNC and press products of its subsidiary Gyeongchang Precision and to detect equipment abnormalities, and is working with Computer Mate. Details are being discussed.

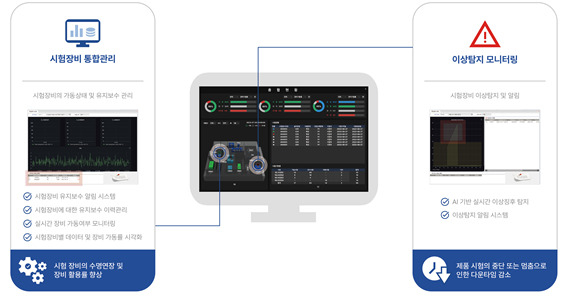

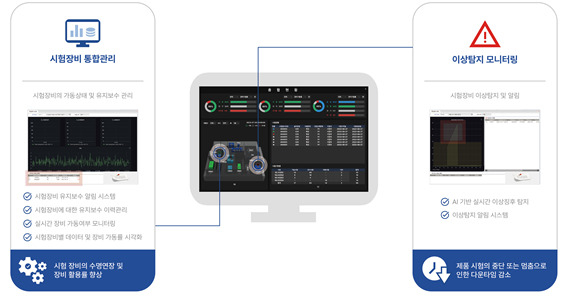

Meanwhile, Computer Mate has built an ‘AI-based test management and test equipment failure prediction solution’ at Pyeonghwa Industry. This product uses AI to notify test equipment failures in advance. Previously, it was only possible to respond when a breakdown occurred in test equipment. However, by predicting and preventing breakdowns, equipment downtime can be reduced. In addition, it not only suggests optimal scheduling when requesting a test, but also facilitates test management by monitoring the operation status in real time through automatically collected data on the test result screen.

Using this product, you can go one step further in predicting equipment failures and shorten physical test lead times through integrated test management, improve test productivity, improve work efficiency through systemization, and immediately respond to abnormal situations through real-time monitoring.

Computer Mate explained that by applying the solution, the test equipment failure rate was reduced by more than 66% from 1.292% to 0.439%. Test scheduling was also reduced from 13 minutes per case to 2 minutes, and test equipment operation rate was improved by 7% from 56% to 60%. Pyunghwa Industry, which introduced the solution, expects an annual 7% increase in operating rate.

Regarding the field application of these solutions, Computer Mate CEO Kim Seong-ho said, “We plan to take the lead in advancing manufacturing innovation by providing the technology accumulated through this project to various manufacturing companies.”

Meanwhile, Computer Mate was launched in 1992 as a company specializing in smart factory solution development and services to help manufacturing companies achieve sustainable management in the era of the Fourth Industrial Revolution.

Over the 28 years since its founding, it has solidified its position by developing and supplying a variety of cutting-edge solutions required in corporate settings. In recognition of its technological prowess and growth potential, it was designated as a Daegu Star Plus company and one of the 100 Star Companies, and is steadily expanding its business not only domestically but also overseas by establishing branches and corporations in Japan and China.

The main product that embodies Computer Mate’s core technology is the ‘Mate’ series, which is optimized for manufacturing sites. It was packaged with its own original technology. Manufacturing Execution System (MES), Point of Production System (POP), Enterprise Resource Planning System (ERP), Supply Chain Management System (SCM), Warehouse Management System (WMS), Quality Management System (QMS), Decision Support System (BI) ), and has a variety of manufacturing-based integrated solutions such as elementary, middle, and high school management systems.

[Source] Daily Payment, Reporter Namkung Sunhee, namkung.sunhee@mkinternet.com https://www.mk.co.kr/news/business/10877668

Provided to Gyeongchang Industry and Pyeonghwa Industry, contributing to improving work efficiency

We are participating as an artificial intelligence (AI) supplier in the Daegu transportation equipment and mechanical materials and parts field hosted by Daegu Techno Park in the 'AI Convergence Regional Specialized Industry Support Project' promoted by the Ministry of Science and ICT and the National IT Industry Promotion Agency (NIPA). Computer Mate (CEOs Sang-in Seo and Seong-ho Kim) announced that it had provided a production line optimization AI solution to Gyeongchang Industry, an automobile parts company, and an AI-based test equipment failure prediction solution to Pyeonghwa Industry. Among these, the solution supplied to Gyeongchang Industries is scheduled to be applied to overseas production sites, so people in related industries are paying attention.

< AI solution applied by Computer Mate to the actuator line of Gyeongchang Industrial Chassis Factory / Provided by Computer Mate >

Computer Mate developed a production line optimization AI solution aimed at minimizing product defect rates and applied it to the actuator line of the chassis factory of Gyeongchang Industrial, a customer company. This solution uses AI to automatically recommend facility condition values, analyzes the correlation between data generated at the production site and the defect rate, and through AI learning, derives optimal facility operation conditions that minimize the defect rate. In particular, in preparation for sudden breakdowns or defects in actuator production/manufacturing facilities and inspection facilities, condition information on the operation status of the equipment is collected and monitored in normal times, and AI determines quality abnormalities in advance through learning and analysis to conduct preventive inspections and advance Action can be taken.

Accordingly, not only can worker dependence be reduced, but defects occurring in the manufacturing process can be reduced, and productivity can be increased through rapid response to abnormal situations and reduction of rework. Computer Mate explained that as a result of using this solution, productivity is expected to increase by 7% per year.

Computer Mate and Gyeongchang Industrial are in the spotlight as exemplary models of cooperation between supply and demand companies that participated in the ‘AI Convergence Regional Specialized Industry Support Project’. The two companies judged that this solution had been sufficiently verified in terms of minimizing defect rates, and agreed to introduce this solution into the process management system (MES) of Kyungchang Industrial's local Mexican branch within this year. The contract size is $100,000. In addition, Gyeongchang Industrial plans to apply an AI-based vision system to the transmission drive device of the Hyeonpoong factory next year, and to use AI models to predict the quality of CNC and press products of its subsidiary Gyeongchang Precision and to detect equipment abnormalities, and is working with Computer Mate. Details are being discussed.

< AI-based test management and test equipment failure prediction solution applied by Computer Mate to Pyeonghwa Industry / Provided by Computer Mate >

Meanwhile, Computer Mate has built an ‘AI-based test management and test equipment failure prediction solution’ at Pyeonghwa Industry. This product uses AI to notify test equipment failures in advance. Previously, it was only possible to respond when a breakdown occurred in test equipment. However, by predicting and preventing breakdowns, equipment downtime can be reduced. In addition, it not only suggests optimal scheduling when requesting a test, but also facilitates test management by monitoring the operation status in real time through automatically collected data on the test result screen.

Using this product, you can go one step further in predicting equipment failures and shorten physical test lead times through integrated test management, improve test productivity, improve work efficiency through systemization, and immediately respond to abnormal situations through real-time monitoring.

Computer Mate explained that by applying the solution, the test equipment failure rate was reduced by more than 66% from 1.292% to 0.439%. Test scheduling was also reduced from 13 minutes per case to 2 minutes, and test equipment operation rate was improved by 7% from 56% to 60%. Pyunghwa Industry, which introduced the solution, expects an annual 7% increase in operating rate.

Regarding the field application of these solutions, Computer Mate CEO Kim Seong-ho said, “We plan to take the lead in advancing manufacturing innovation by providing the technology accumulated through this project to various manufacturing companies.”

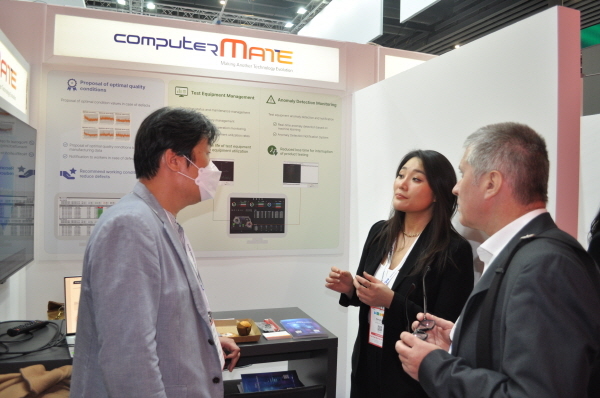

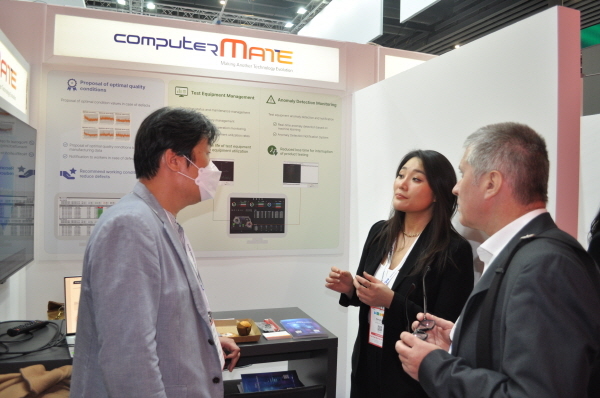

< Computer Mate’s Chief Kim Seong-soo (left photo) is introducing the company’s AI solution to overseas buyers at the ‘2023 Smart City Expo (SCEWC)’ held in Barcelona, Spain for three days from November 7 / Provided by Computer Mate >

Meanwhile, Computer Mate was launched in 1992 as a company specializing in smart factory solution development and services to help manufacturing companies achieve sustainable management in the era of the Fourth Industrial Revolution.

Over the 28 years since its founding, it has solidified its position by developing and supplying a variety of cutting-edge solutions required in corporate settings. In recognition of its technological prowess and growth potential, it was designated as a Daegu Star Plus company and one of the 100 Star Companies, and is steadily expanding its business not only domestically but also overseas by establishing branches and corporations in Japan and China.

The main product that embodies Computer Mate’s core technology is the ‘Mate’ series, which is optimized for manufacturing sites. It was packaged with its own original technology. Manufacturing Execution System (MES), Point of Production System (POP), Enterprise Resource Planning System (ERP), Supply Chain Management System (SCM), Warehouse Management System (WMS), Quality Management System (QMS), Decision Support System (BI) ), and has a variety of manufacturing-based integrated solutions such as elementary, middle, and high school management systems.

[Source] Daily Payment, Reporter Namkung Sunhee, namkung.sunhee@mkinternet.com https://www.mk.co.kr/news/business/10877668

Back to list