Smart Factory Support Project

Business overview

Business overviewAutomation solutions allows you to save money and time by optimizing processes and improve production and work environments through Internet of Things (IoT). Real-time data analysis is capable of proactively diagnosing and preventing problems and producing customized products.

Source: Smart Factory Digital Library (library.smart-factory.kr)

Feature

FeatureSmart factories are different from traditional manufacturing facilities. With application of IoT technology, material status and customer needs can be checked in real time, and efficiently manage costs and materials while producing customized products in the right place and time to improve productivity.

-

01

On the basis of Smart IoT technology -

02

Entire process of value chain

(planning, design, production, distribution, and sales) -

03

All elements in factories are organically connected -

04

Improves productivity -

05

Automation and informatization

(digitalization) through all steps -

06

Minimum cost and time -

07

Production of customized products -

08

Energy saving

Source : National Institute of Technology and Standards Technical Report No. 78, Smart Factory Technology and Standardization Trend_Compositions of Smart Factory

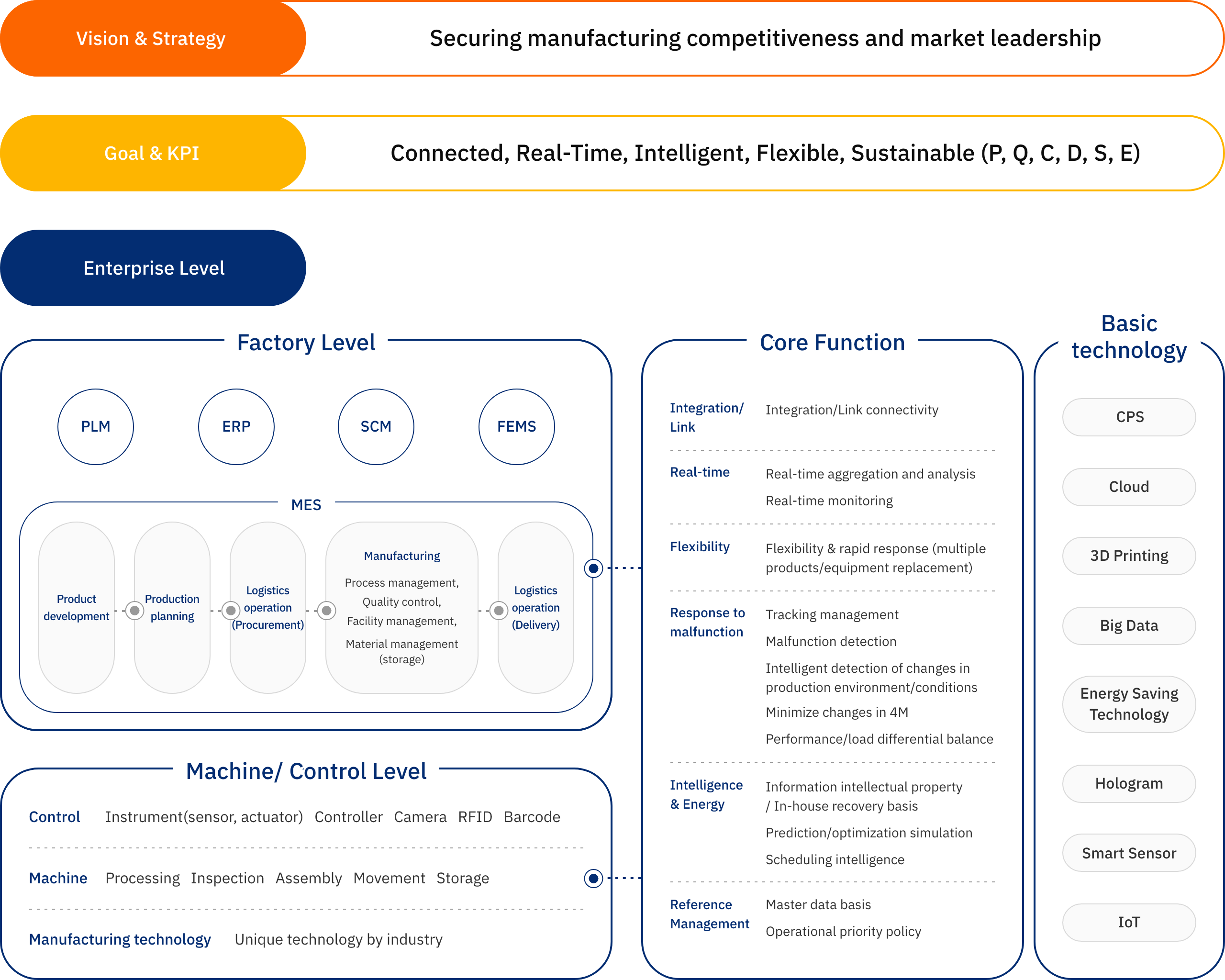

Operating System Framework

Operating System Framework

Smart Factory Smart Level Reference

Smart Factory Smart Level Reference| Classification | Site Automation | Factory Operation | Business Resource Management | Product Development | Supply Chan Management |

| Advancement | IoT1)/ IoS2) basis | Business CPS3) network collaboration in the Internet space | |||

| IoT/IoS | IoT/IoS (Module) Diagnosis and operation based on big data |

Big Data/ Design·Development Virtual Simulation/ 3D Printing |

|||

| Mid Level 2 | Facility control automation | Real-time factory control | Factory operation integration | Standard information/technical information creation and connection automation | Multi-product development collaboration |

| Mid Level 1 | Equipment data automatic aggregation | Real-time decision making | Integration between functions | Development and operation of reference /technical information | Multi-product production collaboration |

| Basic Level | Performance aggregation automation | Process logistics management (POP) | Management function central function individual operation |

CAD project management | Reliance on a single company |

| ICT not applied | Manual operation | Manual operation | Manual operation | Manual operation | Collaboration through phone and email |

< Based on target level: e-nara standard certification KS X 9001-1 (23p) – Level overview diagram >

- 1) IoT : Internet of Things

- 2) IoS : Internet of Services

- 3) CPS : Cyber Physical System

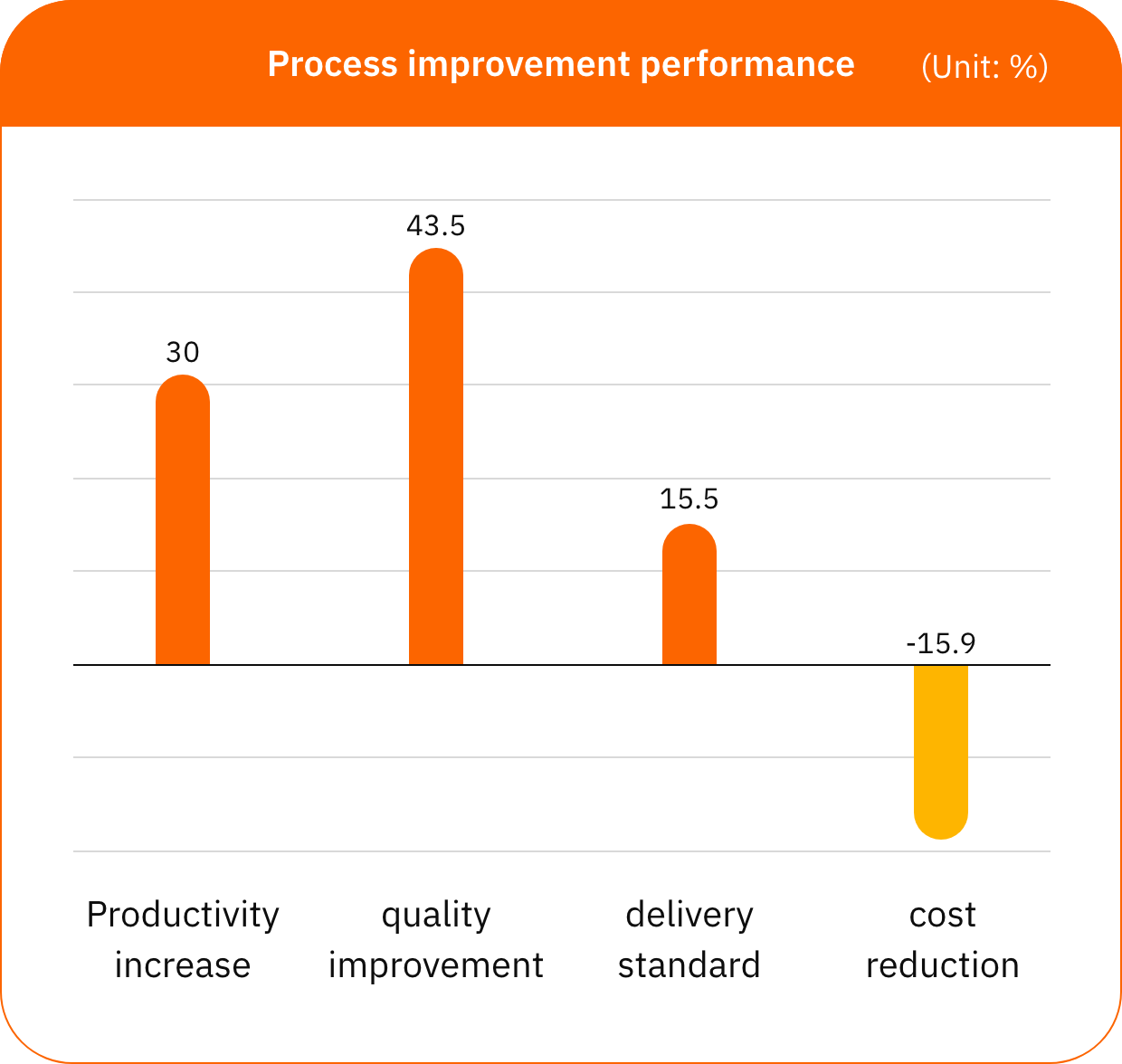

Performance following Smart Factory introduction

Performance following Smart Factory introduction