Product Overview

Product Overview Product Features

Product Features-

Efficient process management

Through the development of equipment and software suitable for the situation in Korea, it is possible to replace imported equipment and proceed with process management more efficiently

-

Easy Automation System

More convenient and easy processes as the existing systems dependent on employees’ manual works are replaced

-

Efficient mixing process

Efficient management due to the automation of mixing processes

Product Competitiveness

Product Competitiveness- Original manufacturing technology for rubber products

- Multiple references for building mixing management system

-

Rubber Roll Mixing Process Control S/W

2007.08.21 Korean Agency for Technology and Standards(KATS)

(MATE-CIM Ver 2.0) -

Production management method of rubber products Patent No.10-0782573

2007.11.29 Korean Intellectual Property Office(KIPO)

Key functions of mixing management

Key functions of mixing management-

01

Improved method of work

Increase the work efficiency by moving from manual works to automated processing

-

02

Improved working environment

Provide a desirable environment for workers by efficiently organizing the workplace environment

-

03

Prevention of errors in processe

Exclude potential errors in the weighing process arising from mistakes of the manual works(Fool-Proof System)*

-

04

Real-time checks available

Check in real time details of work orders and on-site operations

-

05

Accuracy in data management

Accurate management of data related to materials, customers, suppliers, job instructions and work history and applying them to job analysis

-

06

Increased competitiveness

Lower defect rates, improved productivity, and increase in international productivity

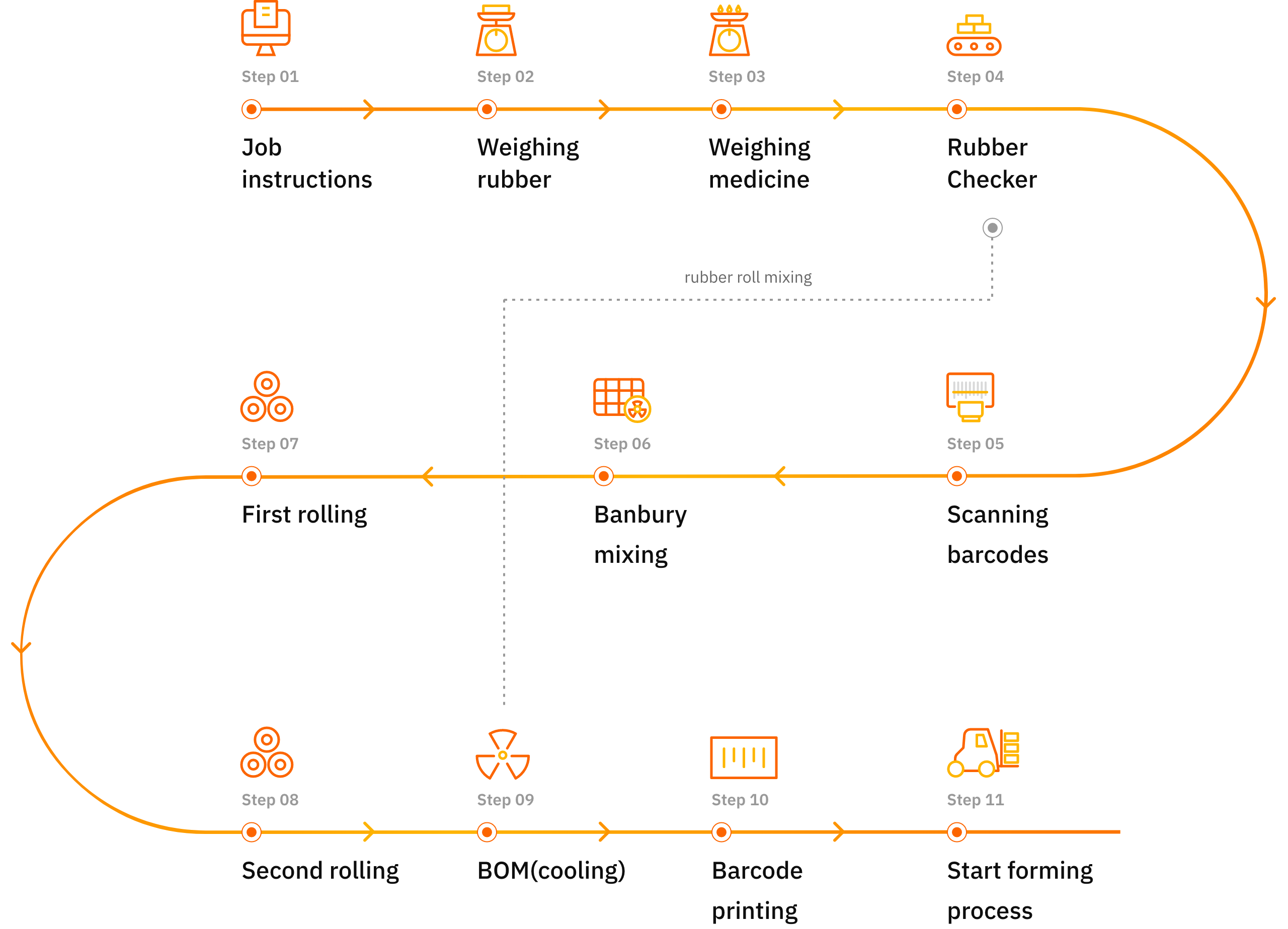

Production processes

Production processes

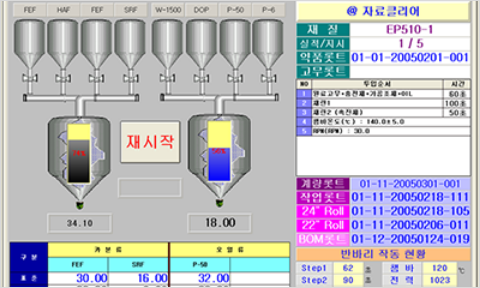

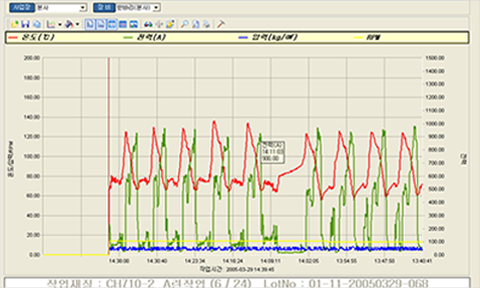

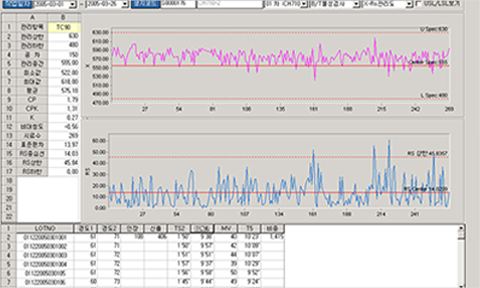

MATE-mixing management system Implementation Display

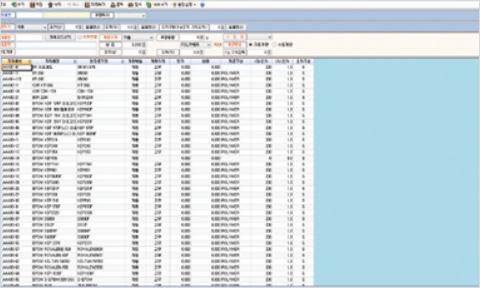

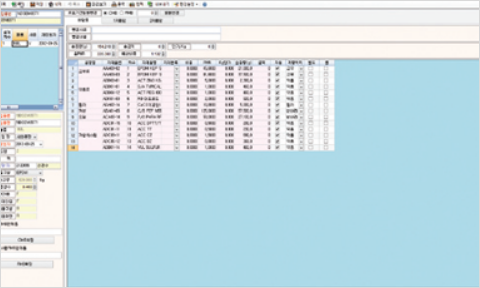

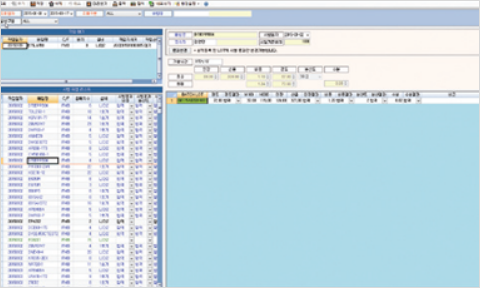

MATE-mixing management system Implementation Display- Composition of the program menu: material registration / operator setting for each equipment / minor chemicals setting / carbon oil setting / communication terminal setting and etc.

- Registration of master data setting and reference to standard information

- Composition of the program menu: register, search for, change, and print the following—mixing charts / changing materials in batches / calculating unit cost of mixing / testing mixing weight

- Prevent errors arising from the existing manual works

- Help with increasing efficiency by preventing misworks

- Composition of the program menu: register job instruction / current work orders / daily report of weighing tasks / current details of weighing / current stock in the weighing works / stock in the weighing process / current measuring works / auto measurement history / current roll mixing works / details of roll mixing works (roll mixing work history) / roll mixing process charts / monitor roll mixing processes / current roller works / details of roller works (roller work history) / roller work charts, arrivals into ripening room / search stocks by expiration dates / departures from ripening room / temperature & humidity in ripening room / checklist of weight when arrived / material usage (by period) / material usage (monthly / yearly) / monthly & yearly work results / work progress by Lot

- Composition of the program menu - register basic data from Rheometer / register basic data from Mooney viscometer / register basic data from tensile tester / register basic data about weight and hardness / criteria for physical property tests / register results from Rheometer / register results from Mooney viscometer / register results from tensile tester / register results about weight and hardness / change results from Rheometer / change results from Mooney viscometer / change results from tensile tester / change results about weight / change results about hardness / daily report of physical property tests / reports of physical property tests by period / statistics out of physical property tests / CPK management

Please leave an inquiry

with your COMPUTERMATE specialist.