Smart Factory

Business Overview

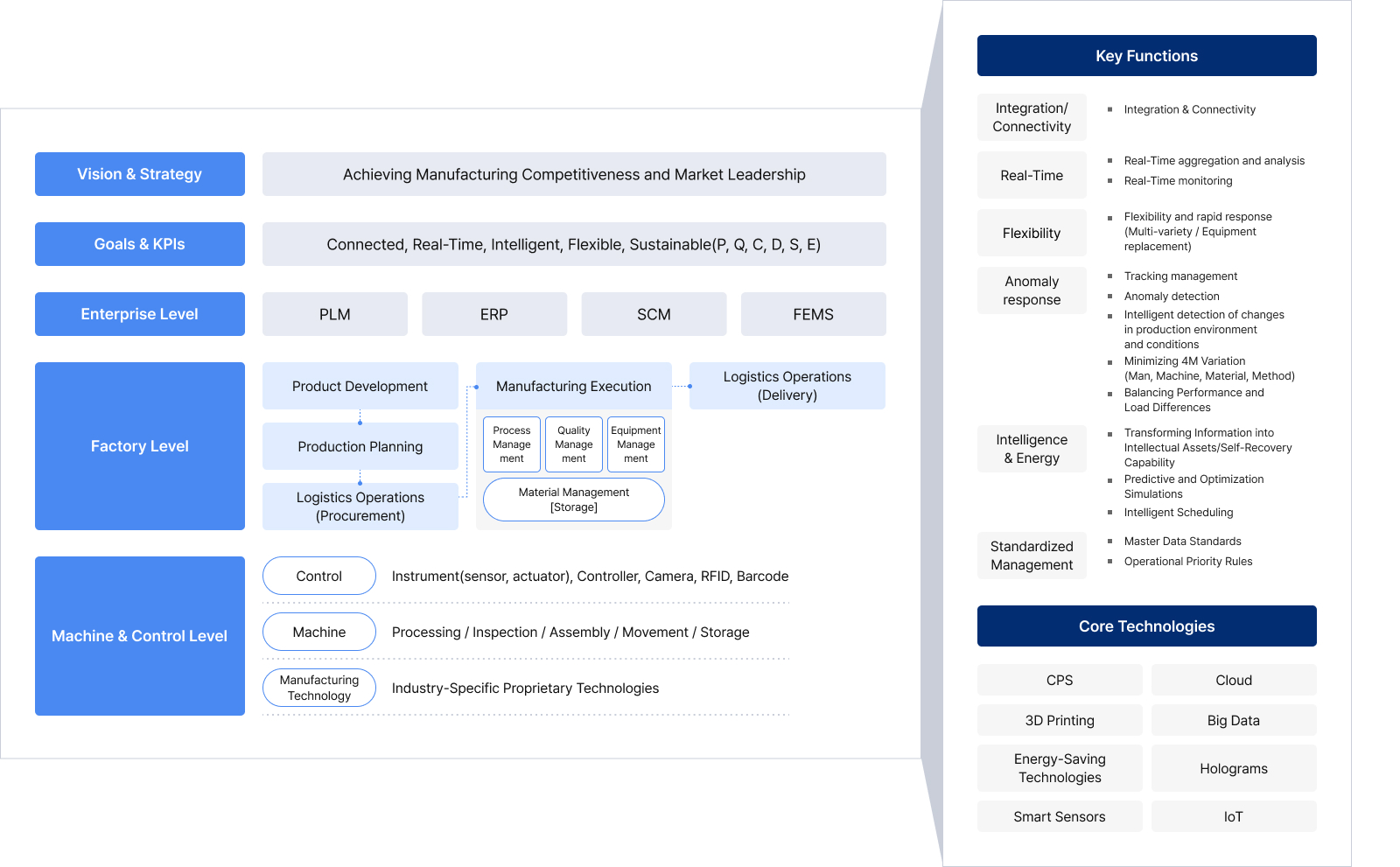

A smart factory is an advanced facility where all production activities in manufacturing are digitized, enabling the creation of an efficient and flexible production system. By applying cutting-edge technologies such as IoT (Internet of Things), big data, artificial intelligence (AI), and robotics, real-time data collection, analysis, and management optimize the production process.

Business Features

-

Connectivity

All equipment and systems are connected via IoT, enabling real-time data collection and monitoring.

-

Automation

Various tasks within the factory are automated, improving the efficient use of human resources and enhancing productivity.

-

Predictive Maintenance

Using AI and big data, the condition of machinery is predicted to enable maintenance, minimizing downtime.

-

Flexibility

Production processes and lines can be quickly adjusted to meet customer demands or respond to market conditions.

-

Data Integration

Production processes and lines can be quickly adjusted to meet customer demands or respond to market conditions.

-

Cybersecurity

Enhanced cybersecurity technologies are essential to minimize security threats arising from increased data connectivity.

-

Workforce Reallocation

The implementation of smart factories reduces repetitive tasks, allowing personnel to be redeployed to higher-value activities.

-

Energy Management

IoT and AI are used to monitor and optimize energy usage in real-time, reducing costs and supporting environmentally friendly operations.

Operating System Framework

Smartization Level Criteria

| Category | Field Automation | Factory Operations | Enterprise Resource Management | Product Development | Supply Chain Management |

|---|---|---|---|---|---|

| Advanced Level | CPS based on IoT1) /IoS 2) | Business in cyberspace CPS 3) Network nollaboration |

|||

| IoT/IoS | IoT/IoS Modularization Big Data-based Diagnosis and Operation |

Big Data / Virtual simulation for design and development / 3D Printing | |||

| Intermediate Level 2 | Equipment control automation | Real-time factory control | Integrated factory operations | Automation of standard and technical information generation and connection | Multi-variety development collaboration |

| Intermediate Level 1 | Automatic aggregation of equipment data | Real-time decision making | Cross-functional integration | Development and operation of standard and technical information | Multi-variety production collaboration |

| Basic Level | Automatic performance aggregation | Process and logistics management (POP) | Independently operated functions management-focused approach | Project management using CAD | Dependence on a single parent company |

| ICT Not Applied | Manual work | Manual work | Manual work | Manual work | Collaboration via phone and Email |

Source: Target Level Criteria: e-Nara Standard Certification KS X 9001-1 (p. 23) – Overall Level Diagram

1) IoT : Internet of Things

2) IoS : Internet of Services

3) CPS : Cyber Physical System

Process and Management Improvement Achievements

Improvement

Achievements

Productivity

29.0%

Quality

42.1%

Cost

35.2%

On-time

Delivery Rate

Improvement

Achievements

Employment Rate

Average employment increase 2.1 people per company

Sales Revenue

11.3%

Industrial

Accidents

Source: Korea Productivity Center (May, 2023)