MATE-SCM Supply Chain Management System

Product Overview

MATE-SCM (Supply Chain Management) is a system that supports simplified and standardized ordering tasks to manage procurement processes accurately and in real-time over the internet.

It facilitates real-time information sharing among trading partners using IT including component suppliers, manufacturers, and customers, enabling agile responses to market demands and consumer needs. The system is designed to support accurate and efficient management of orders, receipts, and payments. It databases all information related to orders, such as receipts, outstanding payments, overpayments, suppliers, and materials, to ensure smooth production and delivery.

Key Feature

-

Web-Based System and Security System

Developed an information system based on the internet, enabling real-time processing of tasks without time and space constraints.

Implements a robust security system to protect business operations and information.

-

Scalability-Oriented Design

Designed to fit the workflow of users, accommodating changes in business environments, advancements in information technology, and the accumulation of data.

-

Selection of Verified Products

Selected genuine software that facilitates smooth system development and maintenance for delivery.

Core Functions

-

System Management, Common Code Management, User Code Management, User Permission Management, Client Information Management, Standard Information Management, IP Management, Backup Management, Registration/Modification/Deletion of Items

-

Order Registration/Modification/Deletion, Automatic Orders, Manual Orders, Periodic Orders

-

Inquiry of Production Status

(Linked with MRP)

-

Receipt Confirmation, Receipt Modification, Return Confirmation, Reorder Processing, Scheduled Receipt Inquiry, Outstanding Receipt Inquiry, Receipt Status Compared to Orders

-

Public Bulletin Board, Secure Bulletin Board, Conditional Search/Modification/Deletion

-

Receipt Management Compared to Orders, Delivery Status Inquiry by Item/Period

-

Delivery Operations, Printing of Delivery Instruction Sheets, Delivery Registration, Modification of Delivery Quantities

-

Management/Inquiries/Output by Date/Period/Item

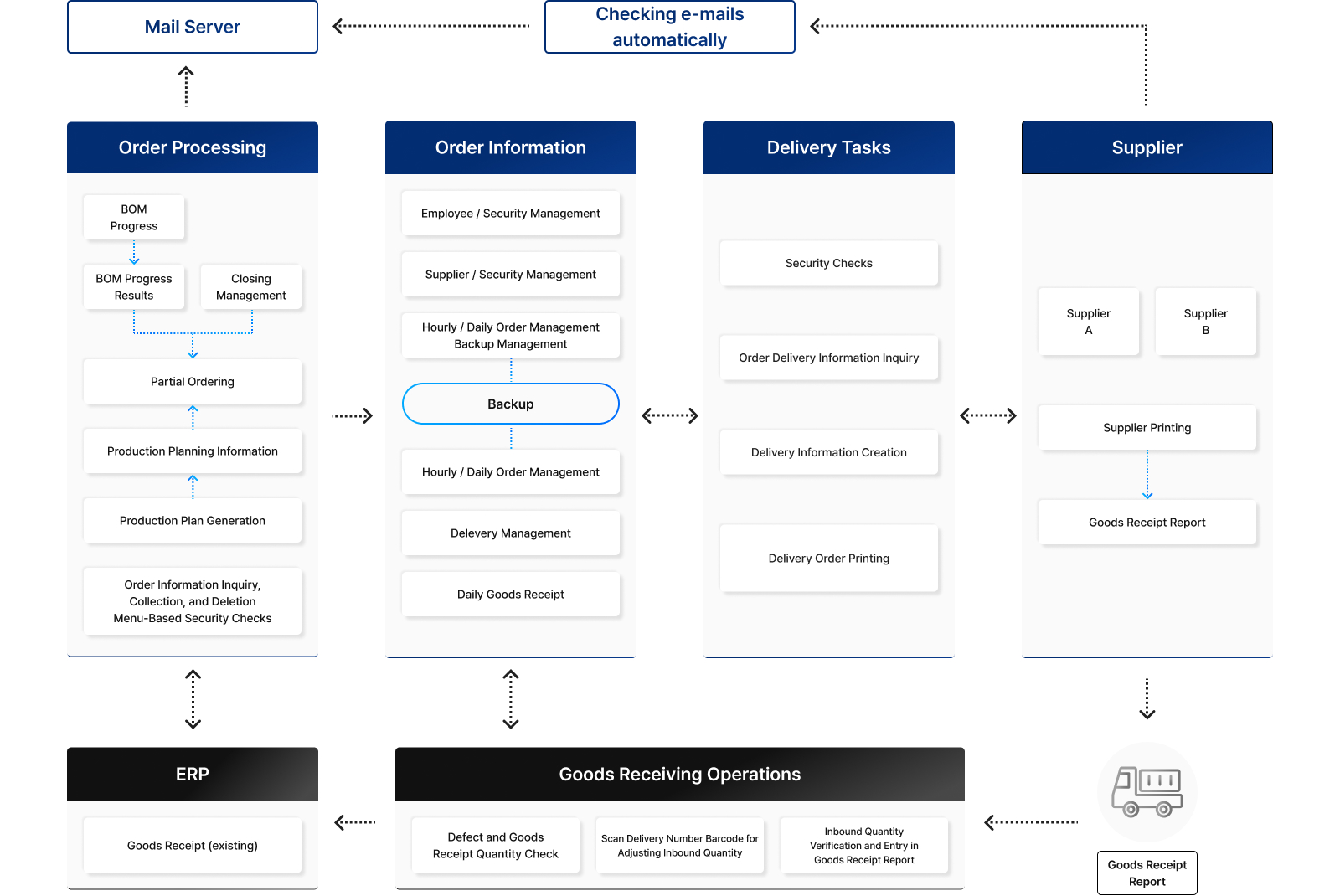

Workflow Diagram

When an automatic order is placed and uploaded to the web, the delivery supplier prints the corresponding shipping order form.

At the same time as printing, the order number is automatically generated as a barcode, which immediately serves as the box instruction.

When goods are received at our company, the barcode on the delivery instruction form can be scanned without the need for a separate verification of the transaction statement, allowing for automatic processing of which company supplied which products.

-

Our Company

-

Web-Based creation and dispatch of delivery instruction forms

Automatic assignment of order numbers as barcodes on documents in the web system

-

Internet

-

Delivery supplier

Receipt and printing (Barcode printed on the delivery instruction form) of delivery instruction forms (WEB/EDI document)

-

Delivery of printed delivery instruction forms and products

-

-

Scanning the barcode on the delivery instruction form / Material confirmation and receipt confirmation

System Flow Diagram

Expected Benefits

-

Standardization of operations, Utilization of information technology, and Cost reduction

Consistent and flexible business processing

Quick and accurate handling of tasks

Ability to process tasks anytime, anywhere

Cost reduction through standardization and digitalization of ordering processes

-

Accurate performance management and Utilization of business information

Saving labor and time through standardization

History management based on accurate data

Business information utilization for ordering, delivery, and task history management

-

Support for production and delivery

Accurate order and receiving management

Convenient and rapid task handling

-

Trust between Suppliers

Facilitated organic cooperation between companies

Minimizes task errors and losses