MATE-CPS Cyber-Physical System

Product Overview

MATE-CPS(Cyber-Physical System) constructs a 3D-modeled virtual environment replicating real-world production sites. Based on real-time process data collected from the production site, it synchronizes the virtual site, visualizes and monitors the operational status, and sends alerts in the event of abnormalities, making it easier to manage manufacturing processes.

MATE-CPS processes and integrates equipment, sensor, and production data collected from processes. Based on this, it transforms physical production models into virtual counterparts for enhanced process monitoring, providing manufacturing process monitoring. It supports visibility through the virtual site and data visualization monitoring, high reliability, which allows quick recognition of situations and optimal response by quickly alerting users of abnormal situations, and interactivity through real-time information-based comprehensive monitoring of the manufacturing process.

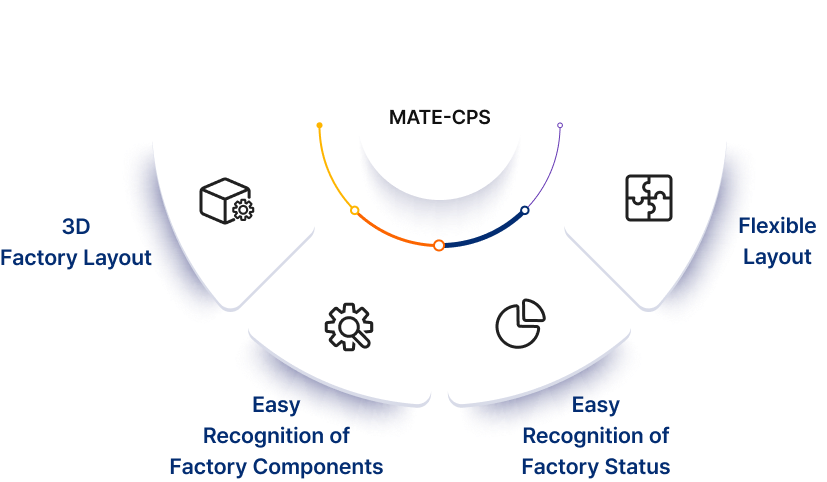

Key Feature

-

3D Factory Layout

3D factory layout similar to the actual production site

-

Easy Recognition of Factory Components

Easy recognition of actual factory components

-

Easy Recognition of Factory Status

Easy to grasp the overall status through real-time data

-

Flexible Layout

User-customizable layout adjustments for equipment position changes

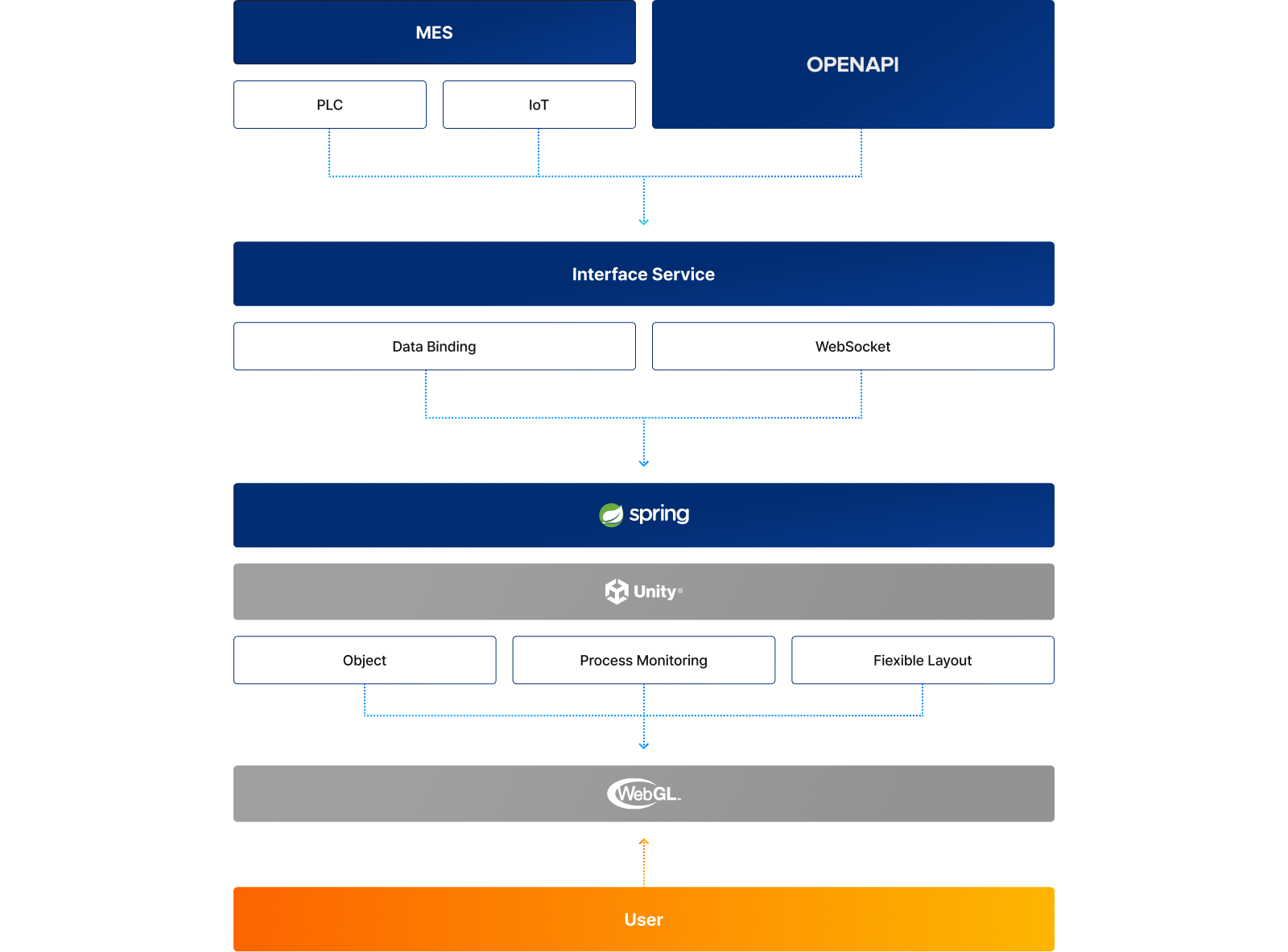

CPS Solution System Flow Diagram

Expected Benefits

-

Visibility

Increased Visibility of Factory Components through 3D Modeled Monitoring

-

Interactionability

Interactivity through Real-time Status Information of Equipment (Quick Understanding of Overall Factory Status)

-

Reliability

It provides high reliability by enabling quick response to equipment failures and anomalies.

-

usefulness

Flexibility and Usability in Changing Process Layouts

Screen Examples

Inventory Status Information

Environmental Status Information (IoT Data)

Equipment Status Information (PLC Data)

Inventory Status Information (Inbound and Outbound Data)

Production Status Information (Performance, Defects, Downtime Data)

Environmental Status Information (OpenAPI Data)