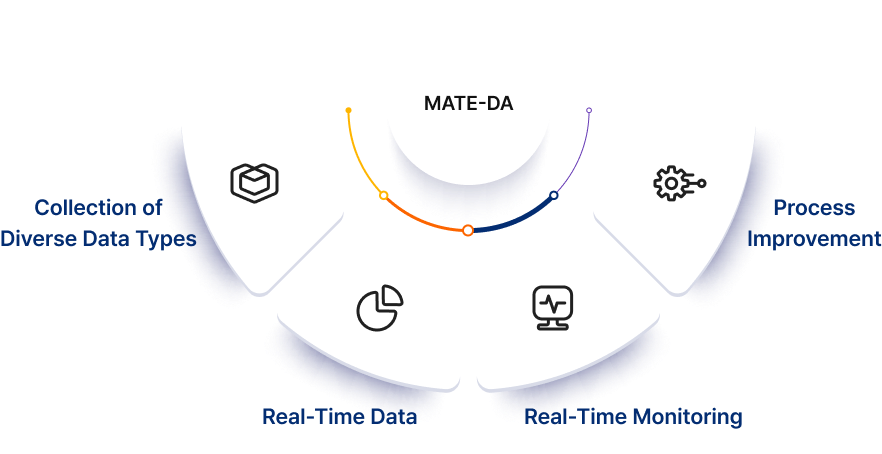

MATE-DA Data Acquisition

Product Overview

MATE-DA (Data Acquisition) is a solution for the real-time collection of manufacturing data from sensors, PLCs, and other sources. It processes and stores data such as sensor information, equipment details, production results, and alarm histories through OPC UA communication, leveraging the OPC Server's key feature of tag data.

Key Features

-

Collection of Diverse Data Types

It collects analog data such as temperature, pressure, and flow, as well as digital input/output data from diverse sources like sensors, PLCs, and DCS, to monitor the overall process situation in real time. This enables the optimization of process control and maintenance.

-

Real-Time Data Synchronization

and StorageSynchronizes the time across all automation systems in the factory to consistently collect and store data. This enhances interoperability between equipment and improves data accuracy, maximizing operational efficiency.

-

Real-Time Monitoring of Equipment

and Energy UsageMonitors the operating status of equipment, energy usage, and utility consumption in real-time, supporting cost reduction and optimal equipment operation. This achieves improved energy efficiency and sustainable factory operations.

-

Data-Driven Process Improvement

Analyzes the collected data to provide solutions for early detection and resolution of issues in the production process. Through data analysis, improvements can be made across the entire process, including increased productivity, enhanced quality, and cost reduction.

Core Functions

Real-time data collection

(sensor information, equipment information, production results,

error logs)

Tag monitoring

Expected Benefits

-

Improvement of Production Efficiency

Enhances productivity by quickly detecting and responding to anomalies in the production process through real-time data collection.

-

Quality Improvement

Strengthens quality management by utilizing collected data to reduce defect rates and facilitate process improvements.

Screen Examples