MATE-MES for Cloud

Product Overview

This solution implements MES operation and functionality in a cloud environment, standardized and optimized based on over 25 years of experience and the know-how gained from delivering MES for over 500 companies.

By utilizing a public cloud, MES can be accessed anytime and anywhere with an internet connection. It operates on a pay-as-you-go model, allowing small businesses with lower usage demands to use the service at a reasonable cost. Additionally, optional features are available as needed, saving time and money and enhancing economic efficiency.

Key Features

-

Smart

Provides a convenient and intuitive user interface, making it easy for users to operate

-

Speed

Enables fast task processing through efficient process management, and can be easily implemented with simple settings

-

Security

Strengthens information protection and stability with strict security technology to ensure the safety of users' assets. In the event of a failure, continuous service is available through a disaster-resistant data center, providing a highly available environment at a low cost

-

Integration

Allows for flexible and efficient business operations and management through an integrated UI and data

-

Cost Reduction

Drastically reduces initial deployment costs by allowing users to use only the specifications, features, and duration they need as a service. The integrated management of software and data increases efficiency in software updates and data maintenance

-

Flexibility

Allows for flexible operation by expanding computing resources as needed and scaling down when they are not required, enabling adaptable usage

Necessity of Adoption

-

Companies that need systematic management but have limited personnel to manage the system

-

Companies that find it difficult to build their own system due to financial constraints and the need for large-scale investments

-

Companies that need an MES that can be easily applied in the short-term

Core Functions

BOM Management

Routing Management

Terminal Management

Item Information Management

Vendor Information Management

Work Order Management

-

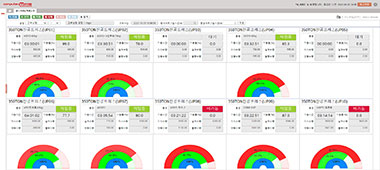

Performance Management(Production Performance Management,

LOT Tracking, Monitoring) Inbound Management

Outbound Management

Outsourcing Management

Purchase Order Management

Delivery Management

Inbound Management

Outbound Management

Inventory Management

Transaction Management

Monthly Inventory Management

Material Stocktaking

Production Stocktaking

Product Stocktaking

Order Management

Inbound Management

Outbound Management

Master Data Management

Incoming Inspection Management

Performance Registration

Performance Inquiry

Delivery Registration

Delivery Inquiry

Outsourcing Management

Equipment Information Management

Inventory Stocktaking

Sales Outbound Registration

Optional

Master Data Management

Mold History Management

Spare Parts Management

Performance Registration (Mold)

Regular Inspection Registration

Routine Inspection Registration

Daily Inspection Registration

Inspection Results Management

SPC (Statistical Process Control) Management

Gauge R&R (Repeatability & Reproducibility) Management

Daily Inspection Management

Maintenance Work Management

Expected Benefits

-

Economic Efficiency

Reduction in infrastructure setup (electricity/network)

Cost savings on hardware operation and maintenance

Shortened MES deployment costs and application time

-

Convenience

MES can be used on various OS and devices (PC, mobile, etc.)

MES can be accessed without time or location constraints

Real-time monitoring and management of work progress

-

Expertise

Professional management and support for hardware and systems

Enhanced security and improved ability to respond to system issues

Maintenance of operational efficiency through continuous monitoring and support

-

Efficiency

Improved work efficiency through a continuous collaboration system

Enhanced data reliability and processing speed

Improved work efficiency through easier information sharing