MATE-Compounding management system

Product Overview

Automation of Process Control and Efficient Management of the compounding Process.

The MATE-Compounding management system enables the automation of the chemical weighing process, one of the most important steps in the rubber manufacturing process. It allows for efficient process management, including compounding management and work management.

Key Features

-

Efficient Process Management

Through the development of equipment and software customized to local needs, it replaces imported equipment and enhances process management efficiency.

-

Simple and User-Friendly Automation System

Transitioning from previous manual processes, the new system offers a streamlined and intuitive workflow for operators.

-

Efficient Compounding Process

Automation of process control enables precise and efficient management of the compounding process.

Core Functions

-

Program Menu Configuration : Register materials,

Assign workers to equipment, Set up small-quantity chemicals,

Set up carbon oil, Setup communication terminals, etc. -

Enables registration and inquiry of master data settings.

-

Program Menu Configuration : Compounding Formula Registration /

Compounding Formula Printing / Bulk Material Change / Compounding

Cost Calculation / Compounding Weight Testing, etc., can be registered,

viewed, modified, and printed. -

Prevents errors caused by manual processes.

-

Boosts productivity by preventing operational mistakes.

-

Collects and visually presents real-time data

from the production site, including process status,

managing alarms, and detecting abnormalities.

-

Collects test data in real-time to analyze process abnormalities

and visualizes various quality indicators in graphs.

-

Program Menu Configuration : Work Order Registration / Work Order Status /

Weighing Daily Report / Weighing Detail Status / Weighing Stock Status /

Weighing Process Stock / Weighing Work Status / Automatic Weighing Records /

Mixing Work Status / Mixing Work Details (Mixing Work Records) / Mixing Process Chart /

Mixing Process Monitoring / Roller Work Status / Roller Work Details (Roller Work Records) /

Roller Work Chart / Curing Room Inbound Status / Stock Inquiry by Expiration Date /

Curing Room Outbound Status / Curing Room Temperature and Humidity Status /

Inbound Weight Checklist / Material Usage Status (Period) / Material Usage Status (Monthly/Yearly)

/ Monthly and Yearly Work Performance Status / Lot-based Work Progress Status.

-

Program Menu Configuration : Rheometer Basic Data Registration /

Mooney Viscometer Basic Data Registration / Tensile Tester Basic

Data Registration / Specific Gravity and Hardness Basic Data

Registration / Physical Properties Test Judgment Criteria /

Rheometer Performance Registration / Mooney Performance

Registration / Tensile Performance Registration / Specific

Gravity and Hardness Performance Registration / Rheometer

Performance Modification / Mooney Performance Modification /

Tensile Performance Modification / Specific Gravity Performance

Modification / Hardness Performance Modification / Physical

Properties Test Daily Report / Periodic Physical Properties Test

Daily Report / Physical Properties Test Statistical Status / CPK Management.

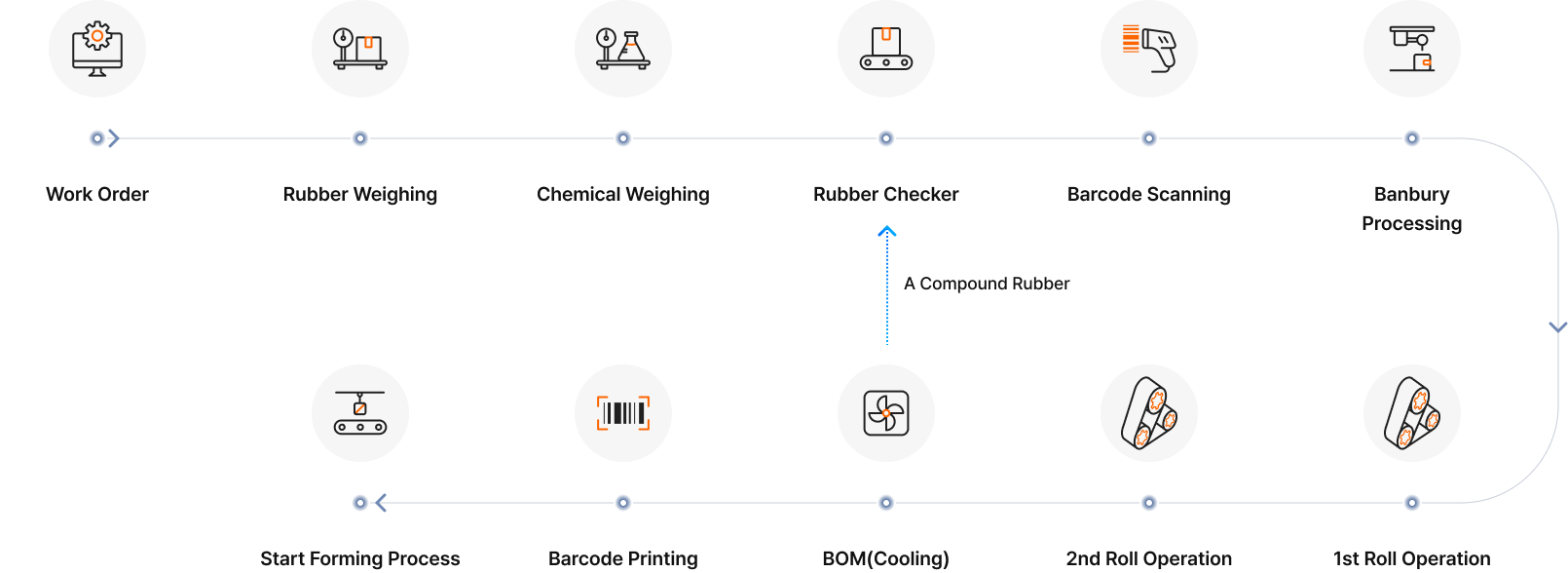

Production Process

Expected Benefits

-

Improvement of Work Processes

Increase operational efficiency by transitioning from manual processes to automation.

-

Improvement of Work Environment

Organize the workplace environment efficiently to provide a better setting for workers

-

Reduction of Work Errors

Prevent weighing errors caused by manual mistakes through the Fool-Proof System*.

-

Real-Time Monitoring

Monitor work orders and on-site activities details in real time.

-

Accurate Data Management

Manage data related to materials, clients, compounding data, work orders, and work records accurately for business analysis.

-

Competitive Advantage

Reduce defect rates, boost productivity, and enhance external competitiveness.

Fool-Proof System: A system designed or maintained to ensure quality and safety by maintaining the reliability of an item, even if inappropriate actions or human errors occur. It enables lot traceability of defective products, from parts to finished goods.